August 2, Kunshan Metal Factory Explosion. On the 4th, the state council’s“8.2” special major explosion accident investigation team made a preliminary judgment, summarizing five major reasons, one of the important reasons is: the dust removal equipment is not in accordance with the provisions for each post design independent dust removal device, dust removal capacity is insufficient. In view of the security risks exposed in this incident, the State Council Security Committee has determined that, grasping the coal mine, flour, sugar, textile, sulfur, feed, plastic, metal processing and grain depot and other factories and mining enterprises that are prone to dust fire and explosion accidents, an all-round special inspection on dust control will be carried out nationwide immediately.

The Donaldson Group is the drafter and principal Standard setter of the NFPA National Fire Protection Association’s Standard on Explosion Protection by Deflagration Venting, it has also obtained the European Atex Explosion Protection Directive (technical requirements for the application of equipment intended for use in potentially explosive environments-basic health and safety requirements and conformity assessment certificates that must be applied before the equipment within its scope of use can be placed on the European market) .

As a global leader in industrial air filtration, Donneson (China) trading and Donaldson (Wuxi) Filter Co. , Ltd. would like to draw on Donaldson Torritt’s nearly 100 years of practical experience in dust removal, in response to the government’s decision-making, interested in solving the dust problem of the various industries to contribute a modest contribution.

Why dust collectors should be part of your strategic decision:

Many manufacturing processes may eliminate flammable dust and fumes, however, it is likely that a suitable and efficient industrial dust removal and ventilation system will be required to control the dispersal of dust in the plant. A well-designed, easy to maintain and operate industrial dust ventilation system, including the reasonable suction hood, the appropriate pipe size and the correct selection of dust collectors, it provides efficient dust control and helps to control dust dispersion, not only reducing the frequency and cost of room cleaning, but also helping to reduce the risk of dust explosion in equipment, especially destructive secondary explosions。

The basics:

Many manufacturing processes produce very small particles of dust that can be dispersed in the air and can easily remain on factory surfaces and crevices. These dusts not only increase cleaning efforts, but if the dust is flammable, there is a possibility of disturbance and explosion.

It is necessary for the factory leader to understand the danger of flammable dust and make sure to control the dust. Donaldson Torritt provides appropriate dust collectors to support your control strategy for handling combustible dust by communicating with you and your professionals about equipment and solutions for fire and explosion protection. Flammable dust usually has the risk of combustion or explosion, so these risk factors must be separately given attention and management, to minimize the risk of explosion.

The three elements of combustion (fire triangle)

Fire management strategies usually focus on controlling or eliminating one of the three factors that can cause a fire, the so-called“Three factors of combustion”, and controlling one or more of them can reduce the risk of fire.

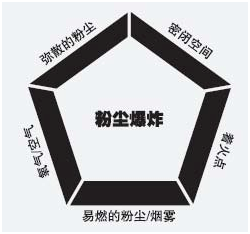

Five elements of explosion

Explosion risk management strategy to consider more elements, the so-called”Five elements of the explosion.”. On the basis of the three elements of combustion (oxygen, combustibles, temperature to ignition point) , add two necessary factors that will lead to explosion, “Diffuse dust” and”Confined space”. Similar to fire control strategies, the risk of explosion can also be reduced by controlling or eliminating one or more elements. Many explosion risk management strategies focus on the three elements of combustion control, while some focus only on the two elements of dust dispersion or confined space control, this strategy must also take into account the risk of combustion.

Main means of dust explosion protection:

The NFPA National Fire Protection Association’s Standard on Explosion Protection by Deflagration Venting was drafted by Donneson, and the main Standard was also developed by Donneson, this fully demonstrates and affirms Donneson’s outstanding ability in flammable dust explosion protection. Donneson dust collectors are designed to contain a variety of explosion-proof configurations, which can effectively reduce the risk of dust explosion.