Various purification methods for organic waste gas

1、Adsorption method

Adsorption is a traditional method for removing adsorbable VOC components or recovering solvents from organic waste gases. The principle of adsorption operation is that the gas components (adsorbates) that need to be separated in the gas phase can selectively combine with the solid surface (adsorbent), and then desorb and return to the gas phase. Adsorption is usually divided into physical adsorption and chemical adsorption. The purification of VOCs mainly adopts physical adsorption methods. Compared with other methods, adsorption methods can adsorb components with very low concentrations (even trace amounts), which can be greatly enriched after desorption. Therefore, solvent vapor can be removed from the exhaust gas and the solvent can be recovered by separation. It has many advantages: it does not require water, does not require auxiliary fuel, and can adapt to changes in exhaust gas concentration and adsorb halogenated hydrocarbons and volatile components containing inorganic substances.

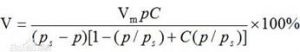

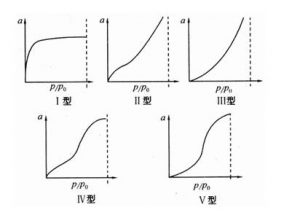

The typical adsorption isotherm curve is shown in Figure 3. In industry, the adsorption isotherm curve equation is commonly expressed by empirical formulas, among which the equation (BET equation) proposed by Bruno, Emmet, and Teller in 1938 to describe the theory of multi molecular layer adsorption is most consistent with the facts

In practical applications, when a gas mixture passes through a bed filled with solid adsorbent, the components need to be separated and adsorbed on the solid surface; When the adsorbent reaches saturation, the adsorbed substance is desorbed by heating or depressurization, during which the adsorbent is regenerated. Due to the low adsorption capacity of the adsorbent, at least two sets of adsorbers are required to complete the continuous operation process of adsorption and desorption. If hot air or superheated steam is used for desorption, it can not only increase the bed temperature, but also reduce the partial pressure of the gas components to be adsorbed; The separated gas components are in hot air or water vapor, and are cooled, condensed, and separated. In the case of water vapor desorption, due to the extremely low solubility of most VOCs in water, they condense into two phases, making them easy to separate.

The commonly used adsorbents for organic waste gas purification are activated carbon or activated coke, because they not only have a large specific surface area, but also have excellent adsorption performance for non-polar substances, while their adsorption performance for polar substances such as water is poor, making it possible to conveniently regenerate with water vapor.

2、Absorption method

Similar to adsorption, absorption involves first combining the gas component (absorbent) to be separated with the liquid phase (absorbent), and then returning to the gas phase through regeneration (desorption). The absorption process can also be divided into physical and chemical methods. The requirements for solvents in absorption methods are: high solubility and high selectivity for absorbing substances; Keep the steam pressure as low as possible to avoid causing secondary pollution; Absorbents should be easy to use and regenerate; Has good thermal and chemical stability; Resistant to hydrolysis and not easily oxidized; High ignition temperature; Low toxicity, not easy to corrode equipment; cheapness. Common absorbents include water, wash oil (hydrocarbons), ethylene glycol ether, etc.

The absorption method also has many disadvantages: generally, the investment cost is high, and the operating cost for the circulation and operation of the absorbent is also high. In addition, if the organic components in the exhaust gas are complex, it is difficult to regenerate or many separation devices must be added; It may also generate wastewater and cause secondary pollution. At present, absorption devices are mostly used for purifying inorganic pollutants in exhaust gases, such as HCl, SO2, NOx, and NH3. Only in rare cases, absorption devices are used to purify organic waste gases.

3、Condensation method

The condensation method is mainly used to separate the condensed components in the gas, and is currently mainly used to recover valuable solvents from exhaust gas, rather than achieving environmental emission limits through condensation alone. The principle is: based on the property of substances having different saturated vapor pressures at different temperatures, by cooling or boosting, the partial pressure of the organic components that need to be separated in the exhaust gas is equal to the saturated vapor pressure at that temperature, and then the organic components are condensed into liquid and separated from the gas phase. The condensation method is more effective for high boiling point organic compounds, but less effective for low boiling point ones. Most of them fail to meet the prescribed emission limits.

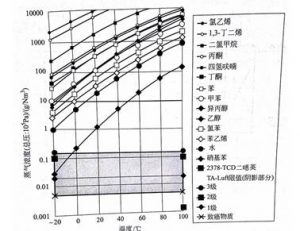

Figure 4 Relationship between vapor concentration and temperature of various organic compounds and emission limits

The range of flow rate and VOC content for treating organic waste gas by general condensation method is: flow rate less than 3000 Nm3/h, and VOC accounts for about 0.5% to 10% of the waste gas. In principle, condensation method should only be used when the exhaust gas treatment capacity is small and the concentration of condensable substances is relatively high. Organic waste gas condenses at low temperatures, and the moisture, CO2, and other components contained in it will freeze, causing partial blockage of the device and affecting heat transfer efficiency. It must be cleaned up. In addition, the concentration of organic components is often within the explosive concentration range, so the safety level requirements for equipment are extremely high.

4、Membrane separation method

Membrane separation method, also known as permeation method, is used in the purification of organic waste gas to separate the carrier air and organic vapor based on their different permeation abilities, or the membrane’s different selectivity for molecules in the gas mixture. Like condensation method, membrane separation method is mainly used in the field of air purification to recover valuable organic compounds, rather than being used separately to treat organic waste gas for the purpose of air purification and meeting emission standards. The concentration of organic waste gas ranges from 10g per cubic meter to several hundred grams, with a waste gas treatment capacity of 100-2000Nm3/h

5、Biodegradation method

The biodegradation treatment of organic waste gas is essentially carried out according to the principle of wastewater biochemical treatment, using microorganisms to oxidize and degrade the organic matter contained in the waste gas into carbon dioxide and water, and the organic matter in the waste gas provides energy and nutrients for microorganisms. At present, there are three main types of equipment for waste gas biochemical treatment: membrane bioreactor, biochemical filter, and biochemical scrubber. Like the biochemical treatment of wastewater, in order for microorganisms to function and have a certain degradation rate, the following conditions must be met: organic matter in the exhaust gas must be soluble in water; Organic matter is biodegradable; The exhaust gas temperature is between 5-60 ℃; The exhaust gas does not contain toxic substances.

6、Photocatalytic oxidation method

When the maximum emission wavelength of the ultraviolet lamp is consistent with the maximum absorption of VOCs, VOCs are directly degraded through a chain reaction of free radicals by ultraviolet light, and this reaction generated by ultraviolet light becomes photooxidation or photolysis. The higher the intensity of ultraviolet light, the easier it is for oxygen in the air to generate ozone, which decomposes into free radicals and intensifies the photolysis process. Moisture in the air can also generate OH under the action of ultraviolet radiation, which also participates in the oxidation of VOCs.

The photocatalytic oxidation method uses catalysts with photocatalytic properties to oxidize VOCs adsorbed on the catalyst surface into CO2 and H2O. Classic photocatalysts are all semiconductors, and TiO2 is most commonly used due to its high absorption of ultraviolet light, high catalytic activity, and chemical stability. In addition, there are ZnO, SnO2, Fe2O3, CdS, ZnS, WO3, PbS, and others.

7、Thermal combustion method

Due to the extremely low concentration of combustibles in organic waste gas, it cannot ignite or sustain combustion on its own. Therefore, it is necessary to use the heat generated by the combustion of auxiliary fuels to increase the temperature of the waste gas, so that VOCs in the waste gas can be oxidized and converted into harmless substances. The first chemical plant of Jinan Chemical Fiber Corporation utilizes this principle and uses an incinerator to treat the exhaust gas of the PTA unit. Three furnaces A, B, and C are set up to switch operation in the order of incineration, emission, and reverse blowing. After incineration, the exhaust gas is discharged into the atmosphere through a chimney.

This method can effectively remove pollutants such as methyl acetate, p-xylene, and CO from PTA exhaust gas, but the removal rate of bromide is low, only 57%. Moreover, the incineration temperature reaches 800 ℃, which requires a large amount of fuel consumption and high operating costs. Improper operation can cause safety hazards and may produce secondary pollutants such as NOx. So it has gradually been eliminated now.

8、Regenerative Thermal Oxidizer,RTO

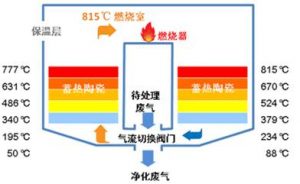

An important part of the operating costs of the thermal combustion method comes from the consumption of auxiliary fuels. So the operating costs are too high and not cost-effective economically. In many cases, the regenerative combustion method is used, which is characterized by the thermal cracking and heat transfer of oxidized exhaust gas being achieved in the same equipment – a heating furnace filled with high-efficiency heat transfer ceramics, also known as regenerative thermal oxidation method.

The basic principle is to heat the organic waste gas to an appropriate temperature (800 ℃), so that the volatile organic compounds in the waste gas are oxidized into carbon dioxide and water in the combustion chamber. The high-temperature gas produced by oxidation flows through the heat exchange chamber, causing the specially designed ceramic block to heat up and store heat, fully utilizing the heat generated by waste combustion to heat the incoming exhaust gas, thereby saving fuel for heating the waste gas (even without fuel). Due to the high thermal efficiency of the process (around 95%), only a small amount of fuel needs to be replenished or no fuel needs to be replenished, greatly saving operating costs. The operation and maintenance of RTO is very simple and reliable, without the need for frequent component replacement, and has a long service life. The disadvantage is that the volume is large and the one-time investment cost is high.

9、Catalytic oxidation method

Catalytic combustion is the process of using a catalyst at lower temperatures (250-400 ℃) to oxidize organic matter through flameless combustion, converting it into carbon dioxide and water. Safe and stable operation, no frequent switching of large valve groups, low operating costs, and no secondary pollution. Therefore, catalytic combustion is the most popular technology among producers for controlling PTA exhaust emissions. Due to the toxicity of bromide in PTA exhaust gas to traditional catalytic combustion catalysts, catalytic combustion systems developed abroad can effectively control bromomethane, benzene, and other VOCs, and comply with the world’s strictest German TA Luft environmental regulations.

Catalytic combustion can control 99% of PTA exhaust emissions. The heat generated during the PTA exhaust gas catalytic combustion process can be used to preheat the exhaust gas at the inlet of the catalytic combustion reactor, fully utilizing the energy generated by the reaction itself. Catalytic oxidation is considered the most feasible and cost-effective VOC treatment method due to its advantages of low conversion temperature and high selectivity, and has been widely applied.