Principle:

Principle:

A heatless regeneration adsorption compressed air dryer is a purification device that utilizes the molecular force on the surface of porous solid materials to extract moisture from gases, resulting in lower dew point temperatures, drier, and cleaner gases.

According to the principle of pressure swing adsorption (PSA), the characteristic of achieving equilibrium between the surface of the desiccant and the partial pressure of water vapor in the air is utilized to adsorb moisture from the air, thereby achieving the goal of removing moisture from compressed air. The dryer is a double tower structure. When air flows through one tower to be dried, the other tower is supplied with a small amount of dry compressed air. The method of pressure reduction and blowing is used to desorb and regenerate the desiccant that has already adsorbed moisture, that is, the desiccant desorbs and discharges the moisture outside the machine. The twin towers work alternately and continuously to output dry and clean compressed air. Its purified air moisture content can reach below the dew point of -40 ℃, thereby obtaining highly dry, anhydrous, oil-free, and high-purity compressed air to meet the needs of gas consumption.

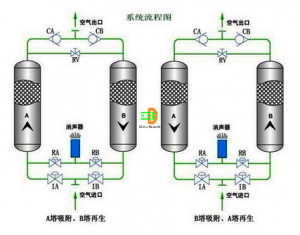

flow:

When the saturated compressed air enters tower A for adsorption and drying treatment through the pneumatic valve, the outlet air contains water and drops to the dew point temperature of -40 ℃ (i.e. becomes dry finished air). 88% of the dry air is input into the finished air pipeline through the check valve (or passes through the dust removal filter to the user), and the other part of the dry air (regenerated gas) is intercepted by the orifice plate and enters tower B for desorption and regeneration of the adsorbed adsorbent. It is discharged to the atmosphere through another pneumatic valve and muffler. This is half a cycle, about 5 minutes. In the second half of the cycle, tower B performs adsorption and drying, and tower A performs desorption and regeneration, with a cycle time of 10 minutes.