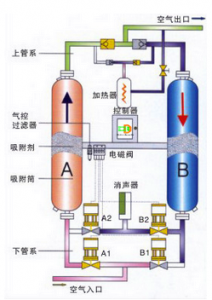

principle:

Micro-thermal regeneration adsorption Compressed air dryer is a kind of porous solid surface of the molecular force to absorb moisture in the gas, and thus obtain lower dew point temperature, dry, clean gas purification equipment. It uses Activated alumina with a diameter similar to that of water molecules as adsorbent, adopts the most advanced temperature-pressure swing adsorption principle in the world, and when adsorbing at room temperature, the partial pressure of water molecules in the air is greater than that of water molecules in the adsorbent. Water molecules enter the adsorbent and condense into water droplets on the surface of the adsorbent.

During regeneration, about 5% of dry air is heated to about 250 ° C by the heater and passes through the regeneration tube, which greatly reduces the adsorption capacity of the adsorbent and causes the water molecules in the adsorbent to escape, at the same time, the heat stored in the adsorption tower is helpful to save the power of the heater. Adsorbents are used in adsorption, regeneration, and adsorption cycles to continuously adsorb and dry Compressed air to obtain deeply dry gases, it has reached the level of similar models abroad and is the first choice for users who wish to obtain dew point gas sources below -40 ° C.

The twin towers work alternately and continuously to produce dry, clean Compressed air. The purified air can have moisture content below -40 â ° C dew point, resulting in a deep-dry, water-free, oil-free, high-purity Compressed air that meets the needs of gas users. Because the heater is used to regenerate gas, the regeneration effect is good and the energy-saving gas consumption is little.