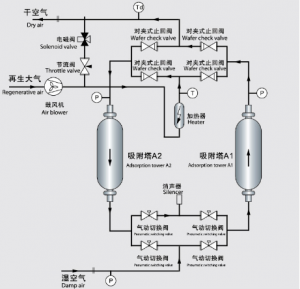

Principle:

The low gas consumption (zero gas consumption) blower thermal adsorption dryer is an energy-saving compressed air drying device that uses the process of ambient air blower regeneration, which can save a large amount of product gas required for traditional process regeneration.

The adsorption principle of the (zero gas consumption) blast heat adsorption dryer is similar to the traditional adsorption process. But its regeneration method is the process of air blowing regeneration, which includes heating and blowing cooling steps. The regeneration gas source during heating comes from the ambient air pressurized by the blower, which is heated to the regeneration temperature by the heater and used as the regeneration gas for the desorption of the adsorber bed. During the regeneration operation, the regenerated heating gas heats and decomposes the adsorption bed layer, and carries the precipitated water vapor with the regenerated gas to remove the adsorber. Regenerative blowing cooling can be achieved by using self dried air, which is then depressurized and used as the regeneration blowing cooling gas, or by air circulation cooling and separation as the regeneration blowing cooling gas to cool the bed layer, in order to meet the needs of the next stage of adsorption work and avoid unstable dew points at the air outlet due to the presence of bed temperature.