Introduction:

The Compressed air precision filter is mainly used for Compressed air cleaning and impurity removal. It filters the dust, water vapor and Compressed air hydrocarbons and bacteria.

In addition, Air compressor lubrication systems produce pollutants such as wear particles and oil. Even oil-free compressors produce these substances. This kind of oil is acidic, is not playing any lubrication of poor quality oil. Corrosion in the Compressed air distribution system can also contaminate the Compressed air

All this dust, oil, and water mix together to form a highly corrosive sludge that rapidly wears out pneumatic equipment, clogs valves, and corrodes pipes, as a result: air leaks, Tool and equipment damage, production stagnation, increased maintenance costs, product scrapping, health and Safety Threats, the working environment is affected.

Features:

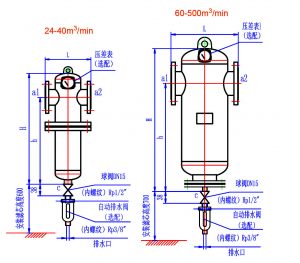

Reasonable structure, small size, light weight;

Automatic and manual sewage discharge methods;

High efficient removal of water, oil mist, solid particles;

Three-stage stage purification treatment, long service life;

With differential pressure indicator display for real-time monitoring of differential pressure;

The filter element filter area increases, the pressure loss is small, the replacement filter element is convenient and quick;

100% removal of particles 0.01 um and above and oil mist concentration 0.01 ppm/wt.

Classification:

V grade oil and dust removal filter

Maximum Temperature: 65 ° C general pressure: 0.2 Kg/maximum pressure: 0.7Kg

Function: filter the large amount of oil and gas in the Compressed air to within 5PPM and remove the impurity particles to 5micron.

Filter material: multi-layer glass fiber filter, precision: 5micron filter oil content: 5ppm maximum pressure: 16Kg/

Class A deoiling and dedusting filter

Maximum Temperature: 65 ° C General Pressure: 0.17 Kg/maximum pressure: 0.7 Kg

Function: filter the oil and gas in the Compressed air to less than 0.5 ppm and remove impurities to less than 1micron.

Filter material: multi-layer glass fiber filter, accuracy: 1micron filter oil content: 0.5 ppm maximum pressure: 16Kg/

B-class deoiling and dedusting filter

Maximum Temperature: 65 ° C general pressure: 0.275 Kg/maximum pressure: 0.7 Kg

Function: fine filter the oil and gas in the Compressed air to 0.01 PPM, and filter the impurity particles in the air to 0.01 micron, high quality oil-free Compressed air.

Filter material: multi-layer glass fiber filter, precision: 0.01 micron filter oil content: 0.5 ppm maximum pressure: 16Kg

C class activated carbon filter

Maximum Temperature: 65 ° C General Pressure: 0.75 Kg/maximum pressure: 0.7 Kg

Function: ozone is normally removed from Compressed air. Very fine oil and gas and ultra-fine particles can be removed. It is commonly used for Compressed air purification in the food and beverage industry.Filter material: activated carbon filter, precision: 0.01 micron filter oil content: 0.003 maximum pressure: 16Kg