How it works: over 750 ° C, the waste gas will be completely decomposed into CO2 and H2O, but at high temperatures, the equipment is easy to deformation, high heat loss, equipment loss. Our company works with South China University of Technology, using the precious metals platinum and palladium as catalysts. The catalysts are involved in the reaction and are reduced at the same time, the complete reaction temperature of exhaust gas can be reached to about 260 ° C by the action of Catalyst, and a great deal of heat energy can be emitted at the same time:

CnH2n-6 + O2 To Burn (a catalyst)→ CO2 + H2O + Q (n≧6)

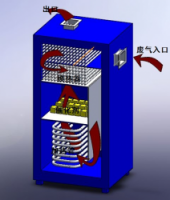

The exhaust gas from the catalytic combustion bed is heated to 280 ° C in the heating chamber and enters the catalytic combustion chamber. With the help of the catalyst, the exhaust gas decomposes fully and gives off a lot of heat, temperature can reach 350 ° C-400 ° C, hot gas flow through the upper heat exchanger heat transfer, the temperature can be reduced to about 100 ° C, saving energy. The heat in the heat exchanger heats the incoming exhaust gas until the whole system is thermally balanced and the heating tubes do not need to be heated.

The Catalyst was prepared with γ-al _ 2O _ 3 as carrier, PT and PD as main active components, and with high dispersity and uniform distribution. The catalyst has the advantages of low initial temperature, high activity and wide space velocity adaptability. Under the conditions of hydrocarbon concentration in the range of 2000-8000mg/m ~ 3, space velocity 10000-20000h ~ 1, and inlet temperature of reaction gas 180-300 ° C, the purification efficiency was ≥98% .