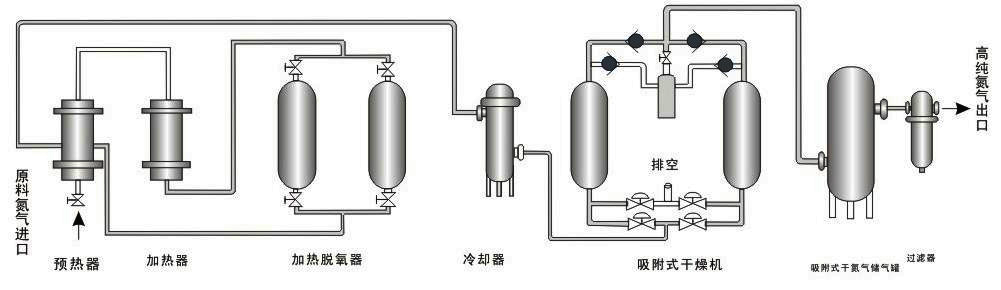

Nitrogen was purified by adding carbon type nitrogen purification device. The principle of palladium carbon fiber deoxidation process is that nitrogen with purity of 99.9% is heated into the deoxidizer containing palladium carbon fiber, the oxygen in nitrogen and the carbon containing the catalyst react with the catalyst palladium as follows:

C + O2 = CO2

Under the action of Catalyst, the chemical reaction is complete and the content of residual oxygen in nitrogen after deoxidation is less than 3 ppm. The deoxidized nitrogen is cooled and enters the adsorber with molecular sieve. The moisture and CO2 in nitrogen are deeply adsorbed by molecular sieve. After filtration, high purity nitrogen can be obtained. The advantages of the process are that there is no hydrogen content in the product nitrogen, and it is especially suitable for the occasions where the hydrogen content is strictly required.

However, the deoxidizer (palladium carbon fiber) in the deoxidizer is of a consumption type. The deoxidizer replacement period of the unit we designed for your company is three months. After three months of use, continuous production can be ensured by switching the deoxidizer, another complete reaction of the deaerator is to replace the deaerator, “Divboair” to take into account the convenience of reloading, the design of feed and discharge mouth, then reload process simplified (each reload only 5 minutes) .

▲The combination of catalysis and chemical adsorption is used for nitrogen purification and argon purification.

▲The use of patented palladium catalyst, high purification depth, strong anti-raw material gas fluctuation ability (200%) . Non-consumable packing, long service life.

▲Imported clean pipes, valves, Swagelok automatic rail welding, patented internal heating and polishing reactor, fully guarantee product quality.

▲Intensive box packaging, automatic operation.

Application area:

▲High purity monocrystalline silicon, wafer epitaxy, large-scale integrated circuit, photoelectric production and other electronic industry gas terminal purification.

▲Gas industry ultra-pure gas production, analysis of zero-point gas preparation.

▲Purification of nitrogen in steel and petrochemical industry.

Stress:0.6~16Mpa content:10~8000Nm3/h granularity:≤0.01μm