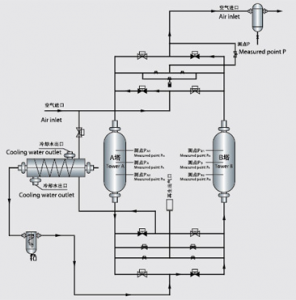

Principle:

The working principle of the dryer is to use the heat generated by the high-temperature air discharged from the air compressor to directly heat and raise the temperature of the adsorbent after the adsorption process, so that the adsorbent can be completely dehydrated and regenerated. Since there is no gas consumption during the heating and regeneration process, energy is saved to the greatest extent possible.

In the compression heating process, the high-temperature and high-pressure gas first enters the regeneration tower of the drying device, causing the adsorbent to heat up and desorb. Then the humid and hot compressed air is cooled to room temperature by the rear cooler, removing a large amount of moisture, and finally enters the adsorption tower for drying, meeting the requirement of a dew point below -40 ℃. After the regeneration heating stage of the regeneration tower is completed, the equipment switches to the cold blowing stage. The cold blowing stage is to use gas that has been treated by a first stage post cooling and separator to cool and blow to the required room temperature for adsorption, and achieve a high degree of drying until regeneration is completed, waiting for the start of the next adsorption cycle.