Features:

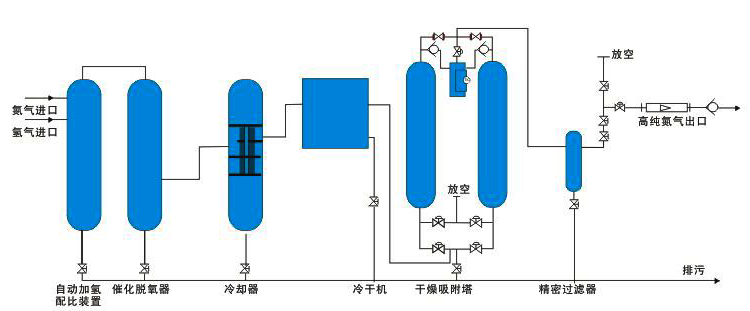

This series of equipment adopts the method of catalytic deoxidation + adsorption drying to remove impurities such as oxygen, water, carbon dioxide and dust in nitrogen to obtain high purity nitrogen. After static mixing, the nitrogen and the added hydrogen enter the heat exchanger, and the inlet gas is preheated by the heat from the outlet of the deaerator, and then enters the deaerator equipped with an efficient hydrodeoxidation catalyst, the impurities of oxygen in nitrogen react with hydrogen to produce water, and at the same time give off a lot of heat, which can form a temperature of about 200 ° C when reacting with 1% oxygen content. Then through the heat exchanger, and then into the dry filter to remove water, carbon dioxide and dust particles and other impurities, thus obtaining high-purity nitrogen.

This series of devices are equipped with automatic fault alarm and shutdown function system: normal temperature deoxidation, no pre-treatment before use, no need for regeneration in use, with good anti-poisoning performance to sulfides, chlorides, ammonia, etc. , the Life is over 5 years: the water content of product gas is low, the dew point is -60 ° C, the hydrogen content of pure gas is ≤5 ppm, the oxygen content is ≤3 ppm.

Technical:

flow:10~2000Nm3/h

Purity:≥99.999%

Stress:0.5~0.8MPa(Adjustable)

Tits: ≤-60℃

Oxygen content: ≤3ppm

Hydrogen content: ≤5ppm