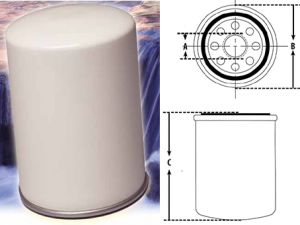

Under normal circulation in the compressor system, the oil itself must be filtered in order to remove impurities that may enter the compressor and damage the system. In order to ensure that the oil through the filter is clean, must use the box or screw-mounted lube oil filter to achieve its function.

While filtering impurities in the 5-25 micron range (depending on the application) , still, the deposition of oil-derived impurities over time (similar to oil separators) , causing the oil filter pressure differential to increase continuously to a large point, in order to ensure the normal operation of the filter, oil filter must be replaced.

Like all our products, oil filters are built with high standards of materials and techniques. By strictly maintaining the number and depth of wrinkles, the filter surface area can be kept consistent, and the use of high standards of filter media, can achieve exceptional filtering level. The use of plasticized Sol and epoxy packaging can prevent leakage. Normally, fluoroelastomer seals are used in synthetic oil applications.