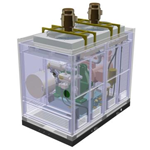

SA Series

SA Series Air-Cooled Derive product requirements and cutting-edge aerodynamics that reflect the market Modular engineering greatly reduces maintenance compared to non-modular compressors Integrated packaging design, each component installed on the base. The fully open structure of low noise enclosure has high openness